Parylene Coating Process

Parylene Coating Process

Applied via vapour deposition in a vacuum chamber, the Parylene Coating Process exhibits superior characteristics and addresses shortcomings of traditional coating processes.

The Parylene coating process involves the CVD method or the Chemical Vapor Deposition method. As a result of the process, parylene is coated on the substrate facades and the molecular level surface. The pin-hole free coatings are conformal, effectually cover crevices, edges, points, sharp ends, internal regions, and there are no gaps at all. The uniformity of the coat is what makes it different from liquid-based coatings like silicone, acrylic, urethane, and more.

Overview

The Parylene coating process is a specialized technique that deposits an ultra-thin, transparent polymeric film at the molecular level. The coating grows one molecule at a time, ensuring deep penetration into gaps, crevices, and multi-layered components.

Process Steps

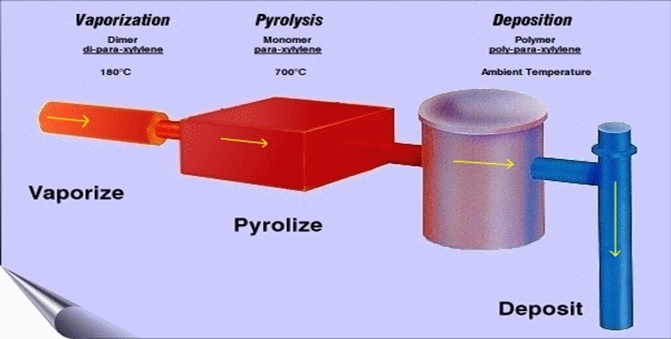

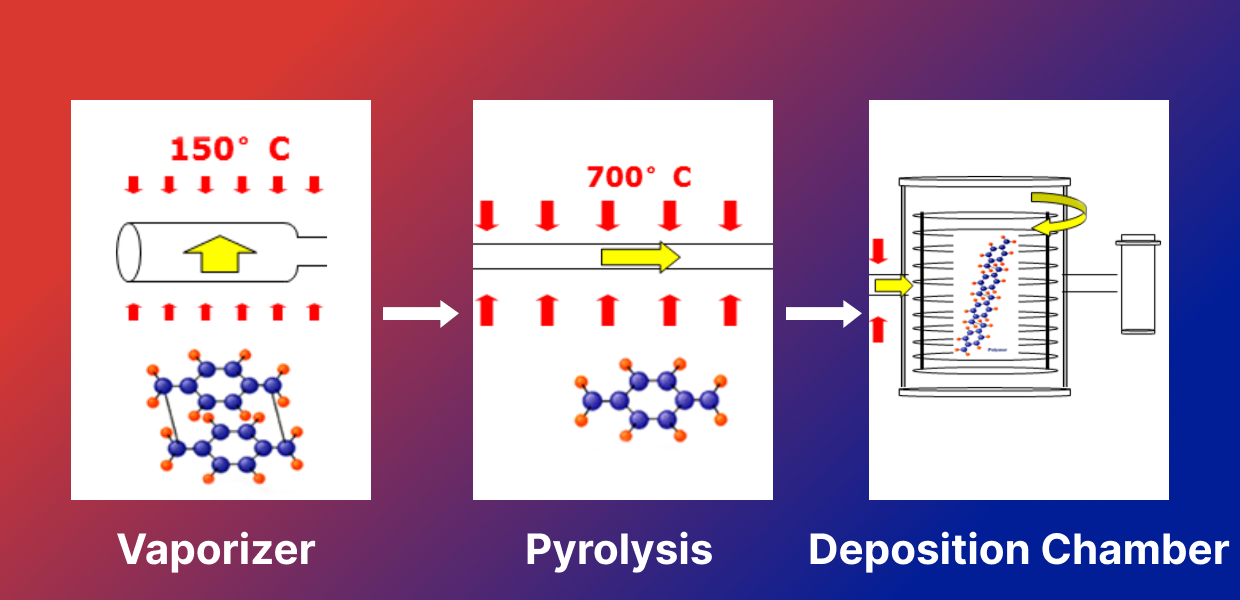

- 1. Vaporization: The raw material (dimer) is heated and vaporized into a gaseous state in vacuum deposition equipment.

- 2. Pyrolysis: The gaseous dimer is cleaved into its monomeric form through pyrolysis.

- 3. Deposition: In a room-temperature deposition chamber, the monomeric gas forms an ultra-thin polymeric film on the substrate surface.

Advantages

Parylene’s gaseous deposition allows it to coat complex geometries effectively. The coating thickness, typically in the micron range, can be adjusted based on the desired application and properties.

Factors Influencing the Coating Process

- Substrate Surface: Parylene adheres to various substrates like plastics, metals, glass, elastomers, and paper. Pre-treatment with A-174 silicone enhances adhesion.

- Cleanliness: The substrate must be free of oils, particulates, or contaminants to ensure optimal adhesion.

- Substrate Preparation: Proper masking is essential to avoid coating areas not intended for coverage, as Parylene coats all surfaces uniformly.

Why Choose Dawn Tech?

Dawn Tech is a leading Parylene coating company in Malaysia, offering high-reliability coating services for diverse industries. Our experienced technicians and robust quality management system ensure precision for all order sizes, from high-volume production to small engineering samples.